Description

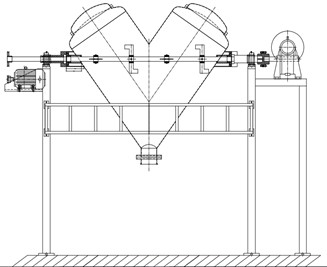

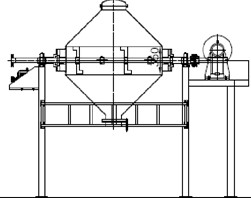

The Double Cone Blender is an essential piece of equipment designed for the homogeneous mixing of dry powders and granules. Its unique conical shape and slant design ensure effective mixing while preventing dead zones, making it ideal for industries such as pharmaceuticals, food processing, and chemicals.

Key Features and Applications:

- Use: The Double Cone Blender is engineered to mix dry powders and granules evenly, ensuring a consistent final product. This makes it a critical tool for industries requiring precision in mixing processes.

- Application: This blender is specifically used for powder mixing across various industries, including pharmaceuticals, chemicals, food, and cosmetics.

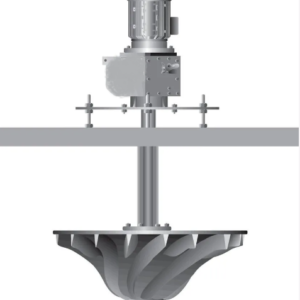

- Principle: The Double Cone Blender operates on a simple yet effective principle. The conical shape of the blender, combined with its slant design, minimizes dead spots and facilitates easy discharge of the blended material. The axis of the blender is slightly offset from the center of the mixing container. As the container rotates, the contents spread, flow, and change positions. This tumbling motion, enhanced by the long corners of the container, creates a rubbing and tumbling effect that ensures quick and uniform mixing of the materials. The mixing vessel is constructed from two conical pieces welded together, with one end for material feeding and the other for material discharge, ensuring efficient and thorough blending.

Material of Construction:

- GMP Model: Crafted entirely from stainless steel, this model is designed for maximum durability, hygiene, and compliance with industry standards.

- STD Model: Features stainless steel product contact parts, while the non-contact parts are made of painted mild steel, offering a cost-effective yet efficient solution.

Model Specifications:

- DCB 25: Gross Capacity: 25 LTRS, Working Capacity: 15 LTRS, HP/RPM: 0.5 HP/36 RPM.

- DCB 50: Gross Capacity: 50 LTRS, Working Capacity: 30 LTRS, HP/RPM: 1 HP/24 RPM.

- DCB 100: Gross Capacity: 100 LTRS, Working Capacity: 60 LTRS, HP/RPM: 2 HP/18 RPM.

- DCB 200: Gross Capacity: 200 LTRS, Working Capacity: 135 LTRS, HP/RPM: 3 HP/16 RPM.

- DCB 300: Gross Capacity: 300 LTRS, Working Capacity: 200 LTRS, HP/RPM: 3 HP/16 RPM.

- DCB 500: Gross Capacity: 500 LTRS, Working Capacity: 300 LTRS, HP/RPM: 5 HP/16 RPM.

- DCB 1000: Gross Capacity: 1000 LTRS, Working Capacity: 700 LTRS, HP/RPM: 10 HP/12 RPM.

- DCB 2000: Gross Capacity: 2000 LTRS, Working Capacity: 1300 LTRS, HP/RPM: 15 HP/10 RPM.

The Double Cone Blender is designed for ease of operation, reliability, and efficiency in mixing, making it an indispensable tool for your production line.

For pricing and additional details, please click the “Get Quote” button.

Don’t forget to check our Terms and Conditions of Sale before placing your order.