Description

The Multi-Mill is a high-efficiency portable unit designed to reduce the particle size of dry materials through variable force swings, beaters with knife and impact edges. This versatile machine is ideal for industries such as pharmaceuticals, chemicals, cosmetics, ceramics, dyestuffs, and food products, where precise particle size control is crucial for product quality.

Key Features:

- Efficient Particle Reduction: The Multi-Mill employs variable force swing beaters with both knife and impact edges to achieve efficient particle size reduction. The materials are processed through a selected screen, which controls the final particle size, ensuring consistency and quality.

- Wide Range of Applications: This machine is widely used in various industries including pharmaceuticals, chemicals, cosmetics, ceramics, and food processing, making it a valuable asset for any production line.

- Portable and Flexible: Designed for easy movement and flexibility, the Multi-Mill can be easily integrated into different stages of production. It is suitable for a range of materials and processing conditions.

Material of Construction:

- GMP Model: Constructed entirely from stainless steel, this model ensures the highest standards of hygiene and durability, ideal for pharmaceutical and food industries.

- STD Model: Features stainless steel for product contact parts and painted mild steel for non-contact parts, offering an economical option without compromising on performance.

Model Specifications:

- 1 HP Multi-Mill:

- Output: 5 to 50 kg/hr

- Screen Size: 150 ID x 95 HT mm

- Charging Height: 1070 mm

- Discharging Height: 500 mm

- Motor: 1 HP / 0.75 KW

- 2 HP Multi-Mill (Standard):

- Output: 25 to 200 kg/hr

- Screen Size: 260 ID x 140 HT mm

- Charging Height: 1550 mm

- Discharging Height: 750 mm

- Motor: 3 HP / 2.2 KW

- 2 HP Multi-Mill (High Output):

- Output: 50 to 500 kg/hr

- Screen Size: 300 ID x 160 HT mm

- Charging Height: 1600 mm

- Discharging Height: 800 mm

- Motor: 5 HP / 3.7 KW

The Multi-Mill’s robust design and precise engineering make it indispensable for achieving consistent particle sizes in various industrial applications.

For more information and to request a quote, click the “Get Quote” button.

Please review our Terms and Conditions of Sale before placing an order.

NOTE

- Please do not Pay without calling ( contact no- 8308665243)

10 POT BAIN MARIE - ROUND POT

10 POT BAIN MARIE - ROUND POT  20 INCH ROUND KADAI

20 INCH ROUND KADAI  15X30 INCH DOSA BHATTI

15X30 INCH DOSA BHATTI  6 POT BAIN MARIE - ROUND POT

6 POT BAIN MARIE - ROUND POT  PAIST FILLING MACHINE - PNEUMATIC 10ML TO 100 ML

PAIST FILLING MACHINE - PNEUMATIC 10ML TO 100 ML  Water Cooler 100 Liters

Water Cooler 100 Liters  4 POT BAIN MARIE - ROUND POT

4 POT BAIN MARIE - ROUND POT  8 POT BAIN MARIE - ROUND POT

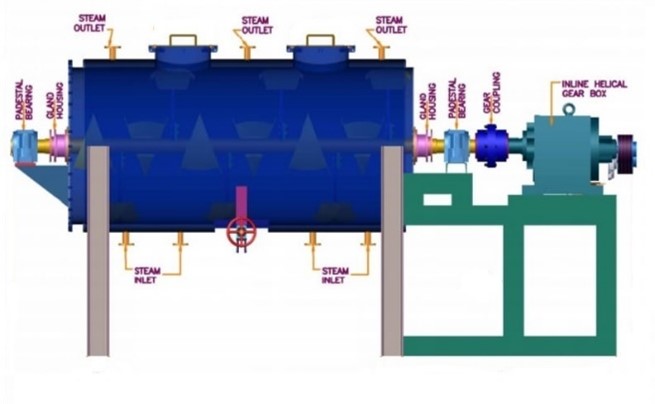

8 POT BAIN MARIE - ROUND POT  Plough Shear Mixer

Plough Shear Mixer

Reviews

There are no reviews yet.