Fluid Bed Dryer

Use – Fluid bed dryers are used for drying materials such as granules, tablets, powders, fertilizers, and plastics. They are particularly popular in production industries like Chemical. Pharmaceutical.

Application – granules, tablets, powders, fertilizers, and plastics

Principle – Here is an explanation of the fundamental idea that drives fluid bed dryer operation. An upward flow of air is permitted through a bed of solid powdered material. This resulted in a velocity that is greater than the total particle setting rate. All of the solid particles will be blasted up and suspended in an air stream when this occurs.

Thus, the solid bed is transformed into the fluidized condition, which is a boiling liquid. The process of fluidizing the bed can then be aided by the use of hot air. This quickens the process of the material drying.

This device comprises of a stainless steel bowl-shaped chamber with a detachable perforated bottom. You must put everything that has to be dried in this basin. The heaters heat the air to a certain temperature once it is introduced from the bottom of a bowl.

The material bed is passed through after the air has been purified with the aid of a filter. The equipment’s top-mounted fans are what create the continual airflow. A control panel is used to alter every aspect of the machine, including the operating temperature and flow rate.

The rapid drying of the material makes this machine famous for its high drying rate. It is always permitted for the materials to be in a free-flowing state. The bags employed in this case have a finger-like shape that helps expand the drying bed’s surface area. During the fluid bed drying process, this kind of design aids in accelerating drying and cutting down on drying time.

Material Of Construction – 1) GMP. Model (Full Stainless Steel), 2) STD. Model (Product Contact Parts Stainless Steel & Non Contact Parts Mild Steel Painted)

| MODEL |

FBD 30 |

FBD 60 |

FBD120 |

FBD200 |

FBD250 |

| VOLUME OF PRODUCT CONTAINER IN LTS. |

95 |

215 |

430 |

590 |

730 |

| BLOWER MOTOR H.P. |

5 |

10 |

15 |

20 |

25 |

| STEAM CONSUMPTION KGS/HR. |

35 |

70 |

100 |

160 |

200 |

| HEATING CAPACITY KW |

18 |

30 |

60 |

|

|

| DRYING TEMP °C |

50-80 |

50-80 |

50-80 |

50-80 |

50-80 |

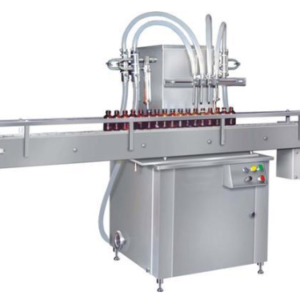

PAIST FILLING MACHINE - PNEUMATIC - 50ML TO 500 ML

PAIST FILLING MACHINE - PNEUMATIC - 50ML TO 500 ML

Reviews

There are no reviews yet.